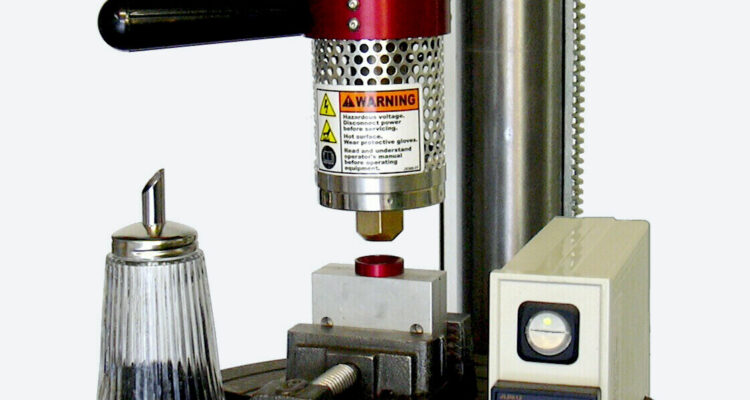

In the fast-paced world of plastic molding, two factors stand out as paramount for success: quality assurance and competitive pricing. Plastic molding professionals are tasked with creating precision-engineered components for a wide range of industries, and achieving excellence in these areas is essential to thrive in this competitive field. Quality assurance is the backbone of any reputable plastic molding operation. Ensuring that every molded part meets or exceeds the specified quality standards is non-negotiable. Quality control begins at the design stage, where engineers meticulously plan every aspect of the molding process, from selecting the right materials to determining the optimal mold design. This attention to detail carries through to production, where state-of-the-art machinery and skilled technicians work in harmony to manufacture each part with precision. To maintain a high level of quality assurance, plastic molding professionals often implement a series of rigorous checks and inspections throughout the production process. This includes visual inspections, dimensional measurements, and material testing to verify that each component meets the exacting standards set by the client.

These measures not only ensure the final product’s reliability but also help prevent defects and reduce waste, ultimately leading to cost savings. Competitive pricing is equally crucial for plastic molding professionals injection moulding companies. In a market where clients demand cost-effective solutions without compromising quality, finding the right balance is essential. Competitive pricing strategies involve a comprehensive analysis of production costs, which includes raw materials, labor, equipment maintenance, and overhead expenses. By optimizing these aspects, plastic molding professionals can offer competitive pricing without compromising quality. One key approach to achieving competitive pricing is through process optimization and efficiency. Investing in cutting-edge machinery and automation technologies can significantly reduce production times and labor costs. Furthermore, continuous process improvement methodologies, such as Lean Six Sigma, help identify and eliminate wasteful practices, resulting in cost savings that can be passed on to customers.

Additionally, plastic molding professionals often establish long-term partnerships with suppliers to secure favorable pricing on high-quality raw materials. This not only helps maintain competitive pricing but also ensures a consistent supply chain, reducing the risk of production delays. Collaboration with clients is another vital aspect of offering competitive pricing. By understanding the specific needs and expectations of each client, plastic molding professionals can provide tailored solutions that meet their requirements without unnecessary expenditures. This customer-centric approach fosters trust and loyalty, paving the way for long-lasting injection plastic molding partnerships. In summary, quality assurance and competitive pricing are the cornerstones of success for plastic molding professionals. By prioritizing these factors, plastic molding operations can consistently deliver high-quality products while remaining cost-competitive in the market. This delicate balance requires a commitment to continuous improvement, efficient processes, and collaborative relationships with both clients and suppliers. In a world where precision and affordability are in high demand, plastic molding professionals who excel in these areas will undoubtedly thrive in the industry.