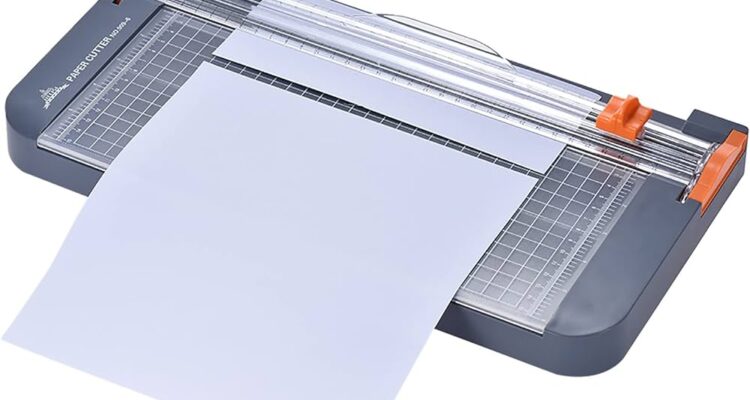

Mastering precision in the realm of paper handling often hinges upon the effective utilization of paper guillotines. These mechanical marvels stand as quintessential tools in various industries, from printing presses to office environments, where exact cuts are paramount. The seamless operation of a paper guillotine combines intricate engineering with ergonomic design, ensuring both efficiency and safety in the cutting process. At the heart of mastering precision lies the precision of the guillotine blade itself. Crafted from high-quality materials such as hardened steel or tungsten carbide, these blades are engineered to slice through stacks of paper with accuracy measured in fractions of a millimeter. The blade’s edge must be maintained meticulously, requiring periodic sharpening and alignment to uphold its cutting prowess. This meticulous maintenance ensures that each cut is clean and crisp, reducing the risk of jagged edges or tearing that could compromise the quality of the final product. Moreover, mastering precision with paper guillotines involves more than just blade sharpness.

It encompasses the entire operational workflow, from initial setup to final output. Operators must meticulously measure and align the paper stack to be cut, taking into account factors such as paper weight, grain direction, and stack height. Even the slightest deviation in alignment can affect the accuracy of subsequent cuts, underscoring the importance of meticulous attention to detail. Safety is another critical facet of mastering precision with paper guillotines. Modern  and cutters are equipped with advanced safety features, including infrared light barriers and two-handed operation controls, to prevent accidents and ensure operator well-being. Regular safety training and adherence to operational protocols are essential to maintaining a safe working environment around these powerful machines. In industrial settings, where large volumes of paper are processed daily, mastering precision requires integrating guillotines into automated workflows. Automated guillotine systems are programmed to execute precise cuts swiftly and consistently, minimizing human error and maximizing productivity. These systems often feature programmable cutting sequences and digital controls, allowing operators to input precise measurements and patterns for complex cutting tasks.

and cutters are equipped with advanced safety features, including infrared light barriers and two-handed operation controls, to prevent accidents and ensure operator well-being. Regular safety training and adherence to operational protocols are essential to maintaining a safe working environment around these powerful machines. In industrial settings, where large volumes of paper are processed daily, mastering precision requires integrating guillotines into automated workflows. Automated guillotine systems are programmed to execute precise cuts swiftly and consistently, minimizing human error and maximizing productivity. These systems often feature programmable cutting sequences and digital controls, allowing operators to input precise measurements and patterns for complex cutting tasks.

Beyond their industrial applications, paper guillotines are indispensable in creative and design industries. Graphic designers, photographers, and artists rely on guillotines to trim prints, posters, and prototypes to exact specifications. The ability to achieve precise cuts ensures that their creative visions are realized with professional polish and accuracy. In conclusion, mastering precision with paper guillotines is a multifaceted endeavor that blends advanced engineering, meticulous maintenance, and operational finesse. Whether used in industrial settings, offices, or creative studios, these machines epitomize precision and efficiency in paper handling. By upholding rigorous standards in blade maintenance, operational workflow, and safety protocols, organizations can harness the full potential of paper guillotines to achieve flawless results in cutting and trimming tasks. As technology advances, so too will the capabilities of these essential tools, continuing to define the benchmarks of precision in paper handling for years to come.