Installing elevator components requires careful planning, precise measurements, and adherence to safety regulations. This process involves multiple steps to ensure the efficient and safe operation of the elevator. Here is a guide outlining the essential steps involved in installing elevator components.

Planning and Design:

Before beginning the installation process, a comprehensive plan must be developed. This includes assessing the building’s structural requirements, determining the elevator’s capacity, and considering any special features or customization. The plan should also comply with local building codes and regulations.

Foundation and Pit Construction:

The first physical step in installing an elevator is constructing the foundation and pit. The pit is excavated to accommodate the elevator components, such as the elevator car, counterweights, and guide rails. The foundation ensures stability and bears the weight of the elevator system.

Structural Support Installation:

Once the foundation and pit are ready, structural lift spare parts are installed. This includes mounting the guide rails, which guide the elevator car’s vertical movement. The guide rails need to be precisely aligned and securely fixed to ensure smooth and accurate operation.

Hoistway and Shaft Construction:

The hoistway, or elevator shaft, is constructed around the guide rails. The hoistway provides the enclosed vertical space through which the elevator car travels. Proper alignment and construction of the hoistway are crucial for the elevator’s safe and efficient operation.

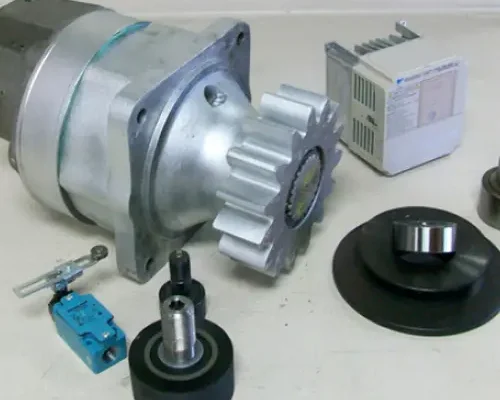

Electrical and Mechanical System Installation:

The next step involves installing the electrical and mechanical systems. This includes wiring for power supply, lighting, and control panels. Safety features, such as emergency stop buttons, intercoms, and fire detection systems, are also installed. The elevator’s drive system, including the motor, gears, and pulleys, is mounted and connected to ensure smooth and controlled movement.

Elevator Car Installation:

Once the hoistway is ready, the elevator car is installed. The car is carefully lifted and secured within the hoistway. It is essential to ensure proper alignment and level the car to prevent any deviations during operation. Safety devices like door sensors and limit switches are connected to guarantee safe entry and exit of passengers.

Counterweight and Balance System Installation:

The counterweight, which balances the elevator car’s weight, is installed next. The counterweight is connected to the elevator car through a system of ropes or cables. Proper balancing is crucial for the elevator’s energy efficiency and smooth operation.

Testing and Inspection:

After the installation of all components, thorough testing and inspection are conducted to ensure compliance with safety standards. This includes functional tests of the elevator’s movement, emergency systems, and safety features. An inspection by relevant authorities is often required before the elevator can be put into service.

Certification and Compliance:

Once the elevator passes all tests and inspections, necessary certifications and compliance documentation are obtained from local authorities. Compliance with building codes, safety regulations, and accessibility requirements is essential to ensure the elevator’s safe and lawful operation.

Ongoing Maintenance and Service:

After installation, it is crucial to establish a regular maintenance and service schedule. Elevators require periodic inspections, lubrication, adjustment, and cleaning to ensure their continued safe and efficient operation. Regular maintenance helps identify potential issues before they escalate, extending the elevator’s lifespan and minimizing downtime.

Installing elevator components is a complex process that demands careful attention to detail and adherence to safety guidelines. Following these steps ensures a successful installation, resulting in a safe and reliable elevator system for building occupants. It is crucial to involve qualified professionals and consult relevant regulations throughout the installation process to ensure compliance and minimize risks.